Boiler Automation

SMEC MARINE

Boiler Automation Products

- Boiler Automation

- Boiler water level control

- Boiler combustion control

- Boiler ACC

- Boiler MDO HFO fuel change

- Flame eye

- Boiler BMS

- Inert Gas generator

- Boiler PLC

Main Boiler Automation Companies

- Aalborg

- Alfa Laval

- Mitsubishi

- Kangrim

- Miura

- Saacke

- Gadelius

Boiler Automation

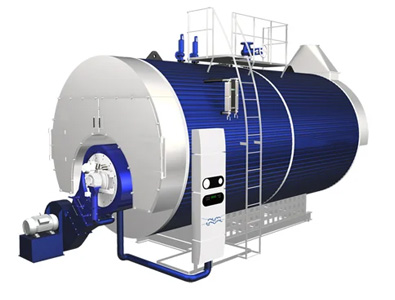

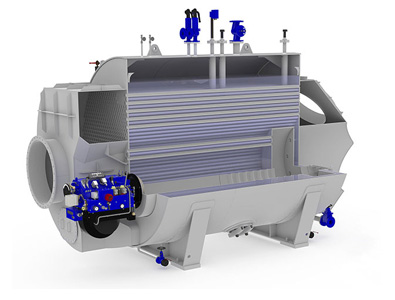

Marine boilers are utilized for auxiliary machinery in the vessel and this is used for engine operations. Boiler automation will be really useful to handle emergency situations. The marine boiler will operate securely and properly because of boiler automation. You can determine the pressure, temperature, and water level by boiler automation. There will be alarms and shutdowns in the boiler automation system to handle emergency situations.

- Water level control

- Burner control

- Pressure and temperature control

- Control of feedwater supply

Boiler water level control

Boiler control is mostly achieved by controlling the feed water pump. The feed water pump should be started and stopped automatically to achieve automation. In case the feed water wasn’t closed at the required time then there will be overflow which can lead to priming. If the pump doesn’t provide water at the required time then there will be thermal stress and overheating of the boiler.

Boiler automation will be a solution for all this. The boiler water level can be determined by utilizing the level control probe and it will be placed on the boiler drum.

Boiler combustion control

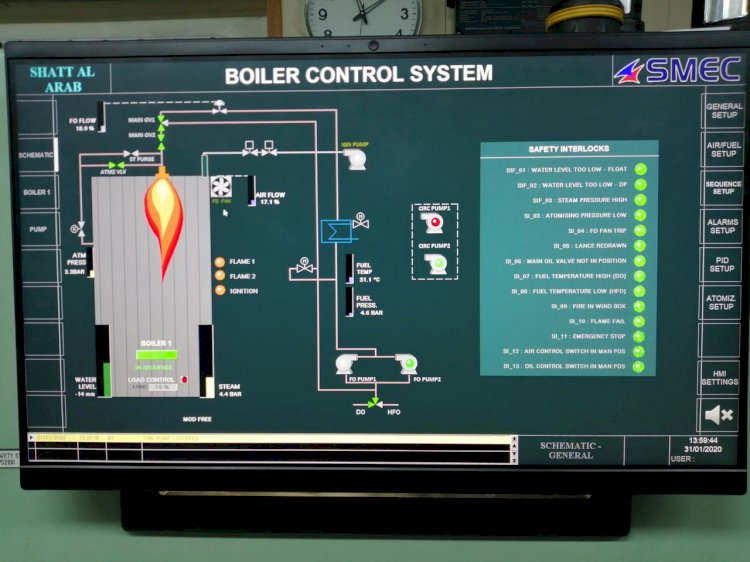

The boiler combustion control can be carried out by utilizing several instrumentation and control systems. The combustion control can be automatically carried out by utilizing the sequence control. According to the load requirement proper firing ratio will be achieved. A proper Air fuel ratio is required to maintain better combustion. PLC is utilized to carry out the combustion control in the marine boiler.

Boiler MDO HFO fuel change

Mostly marine diesel oil is utilized in pressure jet burners. These burners will be able to operate in HFO too. In several boilers rotary burners are used in this burner MDO and HFO are utilized. The fuel changeover in the boiler must be done properly and this changeover could affect certain burners in the boiler. The heavy fuel oil should be in the proper temperature range during the fuel change and we take proper care while doing this. We make this changeover really secure by checking several parameters such as viscosity, temperature, engine load, etc.

Boiler ACC

Boiler advanced combustion control can be used to provide proper combustion under different load conditions. This advanced boiler combustion control can be utilized in the auxiliary boiler which is used in oil rigs and also in different types of vessels. PLC will be connected to the boiler and this will be really useful to determine the boiler status. There are several sensors in the boiler such as the pressure, temperature, etc to determine the boiler status. There is a high signal and low signal selector which can be utilized to handle the load changes. The fuel requirements and the airflow requirements can be determined because of the advanced control of the boiler. This advanced control system will let you control the boiler combustion, steam, water level, etc.

Boiler BMS

The marine boiler must be operated safely and this can be ensured by utilizing the boiler management system. Safe start-up and shutdown of the boiler can be achieved by utilizing the BMS feature. Installing the Burner management system in the marine boiler will reduce the maintenance cost, and improve the uptime. Boiler BMS systems can operate properly with the help of a microprocessor and it can be used to control the boiler operation. The flame detector in the marine BMS will determine the presence of the flame. There are control valves to control the flow of gas or oil in the boiler.

Flame Eye

The flame eye will let us know if the burner is firing or not. This will be really useful to determine the flame’s presence. In case there is any equipment malfunction then it can cause flame failure in the combustion chamber. Falme eye can determine all these problems.

Inert gas generator

The major advantage of utilizing the inert gas in the boiler is that it will remove the flammable atmosphere in the boiler system. This will provide major safety to the boiler automation system. Inert gas is utilized in the boiler exhaust gas inerting system to reduce the hazardous situation.

Boiler PLC

PLC plays a major role in boiler automation. PLC can control the water level in the boiler and also PLC can be utilized to carry out the boiler firing. There are several advantages of using PLC for boiler operations such as reduced maintenance. PLC can be useful to control the water level in the boiler, steam pressure, combustion, control valve operation, and a lot more. The current status of the boiler can be determined by utilizing the PLC. There will be several sensors in the boiler and all of these sensors can be checked by the PLC.

Aalborg

Sales and Services Available, We are the best Boiler Automation Providers in India

Alfa Laval

Sales and Services Available, We are the best Boiler Automation Providers in India

Mitsubishi

Sales and Services Available, We are the best Boiler Automation Providers in India

Miura

Sales and Services Available, We are the best Boiler Automation Providers in India

Saacke

Sales and Services Available, We are the best Boiler Automation Providers in India

Address

#181/2, AL JADAFF DOCKYARD

DUBAI-UAE

Web :

www.smecmarine.com

Email :

[email protected]

Phone :

+971 43 243 744

Mobile :

+971 50 889 0522